Jump to a section...

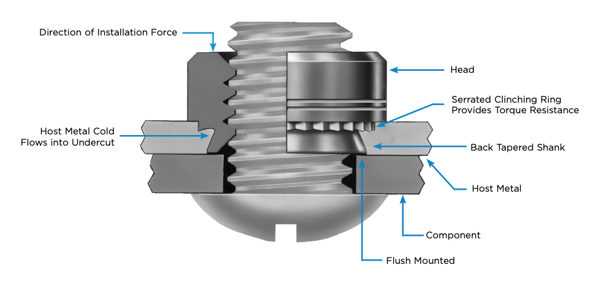

Above and Beyond the Ability of Traditional Screws

Go stronger, cleaner, more reliable

Stronger threads vs. a tapped panel, along with flexible design capabilities for applications using dissimilar materials. Environmentally friendly, with no weld splatter and less energy requirements.

- Permanently mounted blind threads in metal sheets as thin as .040”/1mm

- Self-clinching nuts provide strong load-bearing threads in stainless steel sheets as thin as .8mm

Reduce costs and lead-time

Lower total installed cost, better process control, and reduced opportunity for field failures.

- Easy ordering and lower cost for total install

- Reduced installation time by eliminating secondary operations

TK4™

TackSert® Pins

- Alternative to micro screws to close boxes, eliminates many of the costs of threaded hardware

- Simple, press-in installation. Does not require heat or ultrasonics

- Appropriate for attaching top sheets to bases of cast aluminum, plastics such as ABS, or common magnesium die casting materials such as AZ91D

- Top sheet can be any material

- Ideal for circuit boards

- For use in cases in which disassembly is unnecessary

B™ Self-clinching

Blind Fasteners

- Ideal for use in electrification and busbar applications

- Provide permanently mounted blind threads in metal sheets as thin as .040”/1mm

- Provides barrier to protect threads against foreign matter

- Limits screw penetration, protecting internal components from potential damage

- Installed with any standard press applying a parallel squeezing force

- Available on special order with free-running thread locking feature

THFE™ Heavy Duty Studs

For Thin Sheets

- Ideal for use in electrification and busbar applications

- Enlarged head diameter reduces stress on panel

- Thicker head allows for larger hole in attached panels

- Provide maximum pull through in sheets as thin as .031”/0.8mm

- Clinch design provides high strength

- Install permanently in metal sheets with any standard press applying a parallel squeezing force

Navigation Units

Battery Management Systems

Busbars and Motors

Lighting systems

![]()

Specification and Concept

Connect with one of our senior fastening experts online and in real-time to discuss your most complex fastening questions.

![]()

Teardown

Have an existing product? Our application engineering team disassembles and analyzes your product to recommend fastening alternatives that reduce assembly time and cost.

![]()

Testing

Ensure your product meets requirements. PEMEdge™ Testing Service meets your challenges with accredited testing laboratories all around the world.

![]()

Expert Education

Choose from a comprehensive list of 13 FASTENERClass™ training courses and learn fastener selection and application to help you design the best product.

Talk to an Engineer

Have a question about your application or engineering needs? Get in touch to see how we can help you design a smaller, more durable product with a quicker, cleaner, and more cost-effective assembly. Contact us today to speak with an Automotive ElectronicsFastener expert and engineer.